Stress and Strain

Stress And Strain

Stress (σ) is defined as Force per unit area. It is used to compare forces on different objects. For example intuitively, a very big object on a very big area is as likely to break the floor as a small object on a tiny area. Engineers can use this to analyse forces on small areas and pretty much assume that if the small force is safe on the small area, then the real force will be safe on the real version.

Strain (ε) is the deformation of a material due to stress. It is calculated by dividing the original length of a material by the change in length.

Hooke's law is a good approximation for strains below 5% which is good because we typically work at strains around 1%. At high strains, the relationship between force and extension follows the inter-atomic curve which is actually derived from theoretical physics.

the starting length is a constant and the change in length (x)/ starting length = strain and so it follows that

F ∝ ε

Area is also a constant and so we can divide force by area. This is the definition of stress

σ ∝ ε

σ = Eε

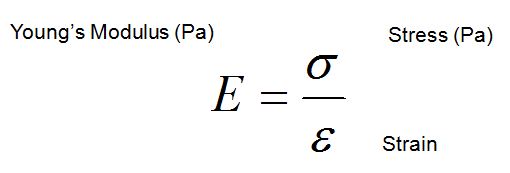

E = σ/ε

where E is the Young's modulus of a material. This is a constant and measures the flexibility of a material. It can be used to compare different materials of different shapes. How flexible a general material is depends on its Young's Modulus.

How flexible a specific object is depends on its Young's modulus (material) and on its shape.

Now we understand this, we can move on to discussing what it means for a material to be strong and why some materials are stronger than others.

Thanks for reading. If you enjoyed this post or any of my others, follow and subscribe to my blog. Feel free to discuss anything related to this post or ask questions in the comments below.

Book Review: Stuff Matters By Mark Miodownik

Did you see my previous post? Click the link below to check it out

Now we understand this, we can move on to discussing what it means for a material to be strong and why some materials are stronger than others.

Thanks for reading. If you enjoyed this post or any of my others, follow and subscribe to my blog. Feel free to discuss anything related to this post or ask questions in the comments below.

Check Out My Other Posts On Materials Science (link to all posts)

Did you see my previous post? Click the link below to check it out

Comments

Post a Comment